Wednesday, May 19, 2021

I'm making a beer for the first time since the end of 2017, so I thought I'd blog about it. This will be the first post in a "beer" series.

I brewed this batch on May 8, 2021. Grace was here and helped out.

I made a big IPA based on the ingredients I had on hand. They're all old ingredients, which might have been problematic, but I think I'll get a solid beer out of it anyway.

| Grain | Quantity | Notes |

|---|---|---|

| American 2-Row | ≈14 lbs. | might have been more |

| American Pilsner | 2 lbs. | |

| Caramel 40L | ≈8 oz. | |

| Roasted Barley | ≈2 oz. | "a handful," for color |

| Hop | Quantity | Boil Time |

| Citra (12.7% AA) | 1 ⅓ oz. | split: 60 min., 15 min., and 2 min. |

| Centennial (12% AA) | 1 ⅓ oz. | split: 60 min., 15 min., and 2 min. |

| Cascade (7.3% AA) | 1 ⅓ oz. | split: 60 min., 15 min., and 2 min. |

| Belma (5% AA) | 1 oz. | split: 60 min., 15 min., and 2 min. |

| Yeast | Quantity | Notes |

| Safale US-05 | 1 pack dry | sprinkled directly into wort |

| Saflager W34/70 | 2 packs dry | added after ≈20 hours; rehydrated in diluted/boiled/chilled wort |

I used my bathroom scale to weigh out the bulk grains from the bags that had been sitting in my refrigerator for five years. At one point, my body weight (which I was using as a zero for weighing the grains) showed a different value, so that's why I suspect the ≈14 lbs. of 2-row might actually have been more. That, or I got a much better mash/sparge efficiency than I've previously measured.

I crushed the grain out back using my trusty modified Victoria grain mill.

Instead of letting the crushed grain collect in a garbage bag, I cut the bag so that it acts as a chute, and the grains fall into a plastic bucket below. Much better. The grain generated a lot of dust, because it was so old and dry.

I mashed thick, using ≈4 gallons of water for ≈16.5 pounds of grain (just less than 1 qt./lb.). I heated the mash water up to 190°F, and dumped it into the empty mash/lauter tun to heat the equipment, with a blanket on the lid.

When the water had cooled to about 170°F, I slowly stirred the grain into the tun. After stirring and letting the mash sit for a few minutes, I measured its temperature to be between 147°F and 149°F, which was below my target of 154°F. However, when I later checked the temperature an hour later, it read 154°F. I trust the second reading, and so the initial mash temperature was likely over 154°F.

After mashing for an hour, an iodine tincture test showed that there was still starch in the solution, so I added about a quart of hot water, stirred, and let it mash longer.

After another twenty minutes, an iodine tincture test still showed starch, so I stirred and covered again at 152°F. Old grain whose enzymes have worn off? Or did I denature them with a too hot initial mash?

After another thirty minutes of mashing, there was still starch in the solution, but at 136°F I gave up and started the sparge.

So, that's a 110 minute mash from somewhere above 154°F down to 136°F, never showing complete conversion. There is a long fly sparge ahead, though, so maybe I ended up getting all of the sugar after all.

Here's my fly sparging setup.

I don't think there's really any reason to fly sparge. Batch sparging and no-sparge brewing proportedly work just as well at the homebrew scale, but I don't know... I like it. It's the most Rube Goldberg part of the process, and in a nerdy hobby, it fits.

I adjust the flow rate both into and out of the lauter tun based on the level of water above the mash as indicated by sharpie markings on the inside of the cooler.

| Time | Level | Notes |

|---|---|---|

| 4:06 PM | 16 cm | runnings at 27°Bx ≈ 1.115 SG |

| 4:14 PM | 17 cm | let's speed up the flow a bit |

| 4:23 PM | 16 cm | |

| 4:37 PM | 14 cm | refilling sparge bucket with hot tap water |

| 4:42 PM | 16 cm | back at it again |

| 4:49 PM | 16 cm | runnings at 8°Bx ≈ 1.0318 SG |

By 4:59 PM (about one hour of sparging) I had collected 8 gallons of 15°Bx ≈ 1.0611 SG wort. I was concerned that if I let this boil down to 5 gallons, that the resulting wort would be way too strong. I decided to let it boil off for a while, to gague the boil off rate, and then discard some wort so that the target 5 gallons of wort at the end of the boil had a reasonable gravity.

During the sparge, I collected the wort between two small pots. When one began to fill up, I'd switch over to the other one and then pour the fuller pot's contents into the brew pot. After collecting about three gallons this way, I fired up the burners under the brew pot so that I could get a head start on bringing the total volume of wort to a boil.

The hot break happened around 5:20 PM, about twenty minutes after I stopped sparging. What a mess.

At some point, I scooped a few quarts of wort out of the kettle. Some I saved in a tupperware container for priming bottles, and some I discarded. The wort that I saved was at 1.068 SG.

The recipe started with one ounce each of the four hop varieties listed in the ingredients section. I planned to blend them together and do 2 ounces at 60 minutes, 1 ounce at 15 minutes, and 1 ounce at 2 minutes. Then I wanted to increase the IBUs by upping the addition at 15 minutes, but I only had one ounce of Belma total. So, I added an additional ⅓ ounce of each of the centennial, citra, and cascade hops to the 15 minute addition.

The actual hop schedule was the following:

| Hop/Quantity | Boil Time |

|---|---|

| ½ oz. Citra, ½ oz. Centennial, ½ oz. Cascade, ½ oz. Belma | 60 min. |

| 7/12 oz. Citra, 7/12 oz. Centennial, 7/12 oz. Cascade, ¼ oz. Belma | 15 min. |

| ¼ oz. Citra, ¼ oz. Centennial, ¼ oz. Cascade, ¼ oz. Belma | 2 min. |

15 minutes before the end of the boil (around the second hop addition), I added the wort chiller to the kettle to sanitize it.

At flameout, I turned on the cold water faucet and continually swirled the chiller in the wort to cool it.

Be sure to fasten the input line to the faucet using a wrench, or it's likely to pop off.

The wort cooled down to 68°F. The original gravity of the batch was 1.082@68°F →1.083 SG.

Before chilling the beer, I noted the level of the wort inside the kettle to be about 5.5 gallons hot. Water has an expansion factor of 1.043 at 212°F, so chilled I had around 5.3 gallons of wort.

Using a sanitized, broken autosiphon, I transferred the chilled wort to a sanitized 5 gallon glass carboy, splashing the stream of wort as it filled the carboy. Then I plugged it and shook the hell out of it for several seconds.

I sprinkled a pack of US-05 dried ale yeast (expired in 2017) into the carboy, fitted a blowoff tube, and placed the fermentor into the chest freezer set to 60°F.

After a day, there was no visible fermentation activity. In retrospect, this is not surprising. A previous batch of similarly strong beer didn't start chugging until the third day. This time, though, I was concerned about the strength of the wort and the viability of the expired yeast. I've read that dried yeast lose their viability at a rate of a couple percent per year, but still...

So, I took two packs of W34/70 dried lager yeast (also expired in 2017), rehydrated them in some of the set-aside 1.068 wort that I first diluted (arbitrarily), boiled, and chilled, and then dumped the whole thing into the fermentor about a day after brewing.

By the following day, fermentation had taken off like a bat out of hell.

Are both yeast strains working on the beer? Is it just the lager yeast? Or maybe it's just the ale yeast, after a two day lag as before? I don't know.

A few days later I replaced the blowoff tube with an airlock, and as of today the batch is still quietly bubbling away.

I plan to bottle condition this beer, priming with the 1.068 OG wort that I set aside on brew day. Maybe I should just use corn sugar instead, I don't know.

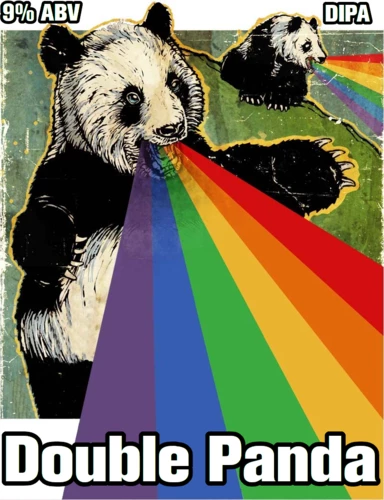

The bottles will get these labels, and caps that look something like this:

The labels I'll print out on glossy paper, cut out with scissors, and then attach to the bottles using a glue stick. The caps I ordered from a printer online; we'll see how they come out.

Yesterday I cleaned out the years of boxes, move-in artifacts, and other detritus from the storage loft in my apartment, so now I have a tidy collection of empty bottles that I can de-label in preparation for filling.

The beer is not yet done fermenting, so I'll update this post come bottling day.

Today was bottling day, and we ended up with 48 12 oz. bottles of primed beer at 9.58% alcohol by volume.

We haven't labeled them yet — still need to update the ABV on the label, print them out, cut them out, and glue them to the bottles.

I primed the beer with the unhopped, unfermented wort that I set aside towards the begininng of the boil on brew day. According to the internet, it's risky to do this, because the fermentability of wort varies from batch to batch (as opposed to glucose solution, which is always the same). I used the Brewer's Friend calculator for "gyle." I hope that the beer doesn't turn out flat.

I boiled and chilled the wort before measuring out the amount specified by the calculator and pouring it into the fermentor using a funnel. Then I gently stirred the wort to mix it in, taking care not to splash.

[It's Spotify's "Yacht Rock," I don't know the song.]

Then my little helper and I siphoned the mixture into 48 sanitized empty beer bottles, capping each one.

I no longer use an auto-siphon. The theory is that it was introducing tiny air bubbles during bottling, causing the beer to go stale almost immediately. I also no longer use a bottling bucket, for the same reason. Now it's just a racking cane into a vinyl tube, all initially filled with sanitizer to start the siphon, and off we go.

Did I mention that I forgot to dry hop this batch? I forgot to dry hop this batch! For such a strong, hop-forward beer as this, it's probably a real loss. I'm curious to find out how to tastes when (if) it carbonates. My guess is that it won't taste right until at least a month in the bottle.

In the mean time, I'll work on the labels.